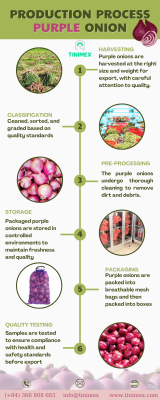

Export Production Process of Purple Onions: 6 Step from Harvesting to Quality Testing

Step 1: Harvesting purple onion

During harvesting, only mature purple onions are selected for export to ensure optimal quality. Skilled laborers inspect the onions to ensure they meet size and color requirements specified by export standards. Onions are carefully handpicked to minimize damage and bruising, ensuring that only premium-quality bulbs are selected for further processing.

Step 2: Classification

Following harvesting, purple onions undergo a meticulous classification process to meet strict export criteria. This step is crucial to ensure that only onions of the highest quality are selected for export.

-

Size Evaluation of Purple Onion:

One of the primary criteria for classification is the size of the onions. Uniformity in size is essential for market appeal and packaging consistency. Onions are sorted into various size categories, ranging from small to large, based on diameter measurements.

-

Color Assessment:

The vibrant purple hue of the onions is a significant characteristic that adds to their visual appeal. During classification, onions are carefully inspected for color consistency and intensity. Any onions with discoloration or blemishes are set aside for further evaluation or lower-grade processing.

-

Quality Inspection:

Quality standards encompass factors such as firmness, texture, and overall appearance. Each onion is examined for signs of damage, such as bruises, cuts, or soft spots, which can affect shelf life and consumer satisfaction. Only onions that meet stringent quality criteria are considered for higher-grade classification.

Step 3: Pre-processing

Pre-processing is a critical step aimed at preparing purple onions for export while maintaining their quality and freshness. Onions undergo rigorous cleaning to remove dirt, debris, and outer layers, ensuring a clean and appealing appearance. Any onions with visible defects or damage are discarded to maintain the integrity of the export batch.

-

Thorough Cleaning:

The cleaning process for purple onions begins with soaking them in water to remove any dirt or debris. They are then thoroughly washed under running water or in automated washing systems to ensure complete removal of any impurities.

-

Removal of Outer Layers:

The outer layers of the onions are often removed to expose the fresh, crisp flesh underneath. This process is typically carried out by cutting or peeling away the outermost layers, ensuring that only the clean inner portion of the onion remains.

-

Inspection and Removal of Defects:

During pre-processing, each onion undergoes meticulous inspection to identify defects such as black spots, swelling, or cracking. Any onions showing signs of these defects are removed to ensure that only the highest quality products are exported.

Step 4: Storage

Proper storage facilities are essential to preserve the quality of purple onions before export. Onions are stored in well-ventilated warehouses equipped with temperature and humidity controls. Storage conditions are closely monitored to prevent sprouting, decay, or any other forms of deterioration, ensuring that onions remain fresh and market-ready until shipment.

-

Facility Requirements:

Purple onions are stored in well-ventilated warehouses with controlled temperature (0-4°C) and humidity (65-70%).

-

Monitoring and Maintenance:

Regular inspections ensure optimal conditions, preventing sprouting, decay, or moisture-related issues.

-

Quality Control:

Onions are stored in FIFO order, regularly checked for quality, and any subpar onions are removed to maintain overall freshness and market readiness.

Step 5: Packaging

Packaging is a critical step in safeguarding purple onions throughout their journey in transportation and storage. The selection of packaging materials is done meticulously to cater to the unique demands of export markets, prioritizing factors such as ventilation, moisture resistance, and protection against physical harm.

-

Selection of Packaging Materials:

Packaging materials are chosen with utmost care to ensure they provide adequate protection to the onions. Common materials include mesh bags, cartons, or crates, selected based on their ability to allow proper airflow while shielding the onions from excessive moisture and external impacts.

-

Ventilation and Protection:

Packaging design emphasizes the need for sufficient ventilation to prevent the accumulation of moisture, which could lead to rotting. At the same time, the packaging must offer adequate protection to safeguard the onions from physical damage during handling and transportation.

-

Labeling and Information:

Each package is meticulously labeled with essential details such as the origin of the onions, onion variety, weight, and handling instructions. These labels serve multiple purposes, including facilitating traceability throughout the supply chain and ensuring compliance with import regulations and quality standards.

-

Customization for Export Markets:

Packaging may be customized to meet the specific requirements and preferences of different export markets. This could involve incorporating multilingual labels, adjusting package sizes to align with market preferences, or adhering to packaging regulations set by importing countries.

Step 6: Quality Testing

Before finalizing the export consignment, purple onions undergo comprehensive quality testing to verify compliance with international standards and regulations. Samples are randomly selected and subjected to rigorous inspection, including size, color, firmness, and absence of defects. Additionally, laboratory tests may be conducted to detect pesticide residues and microbial contamination, ensuring that exported onions meet the strictest quality and safety requirements of target markets.

Conclusion:

By meticulously adhering to export requirements at each step of the production process, producers can ensure the consistent delivery of premium-quality purple onions to international markets. Through careful harvesting, classification, pre-processing, storage, packaging, and quality testing, exporters can meet the diverse demands of global consumers while maintaining the reputation and competitiveness of their products on the international stage.

Our factory

+ Yen Bai factory: Mau A Town, Van yen Dist., Yen Bai Province, VN

+ Ben Tre factory: Hamlet 2, Son Phu Commune, Giong Trom District, Ben Tre Province

Location: No.40 Ngo Gia Tu Str., Duc Giang Ward, Long Bien Dist, Ha Noi City, Vietnam

Contact: +84 366 808 683

Email: info@tinimex.com

Website: Tinimex.com

Fanpage: Tinimex

Store: Tinimex